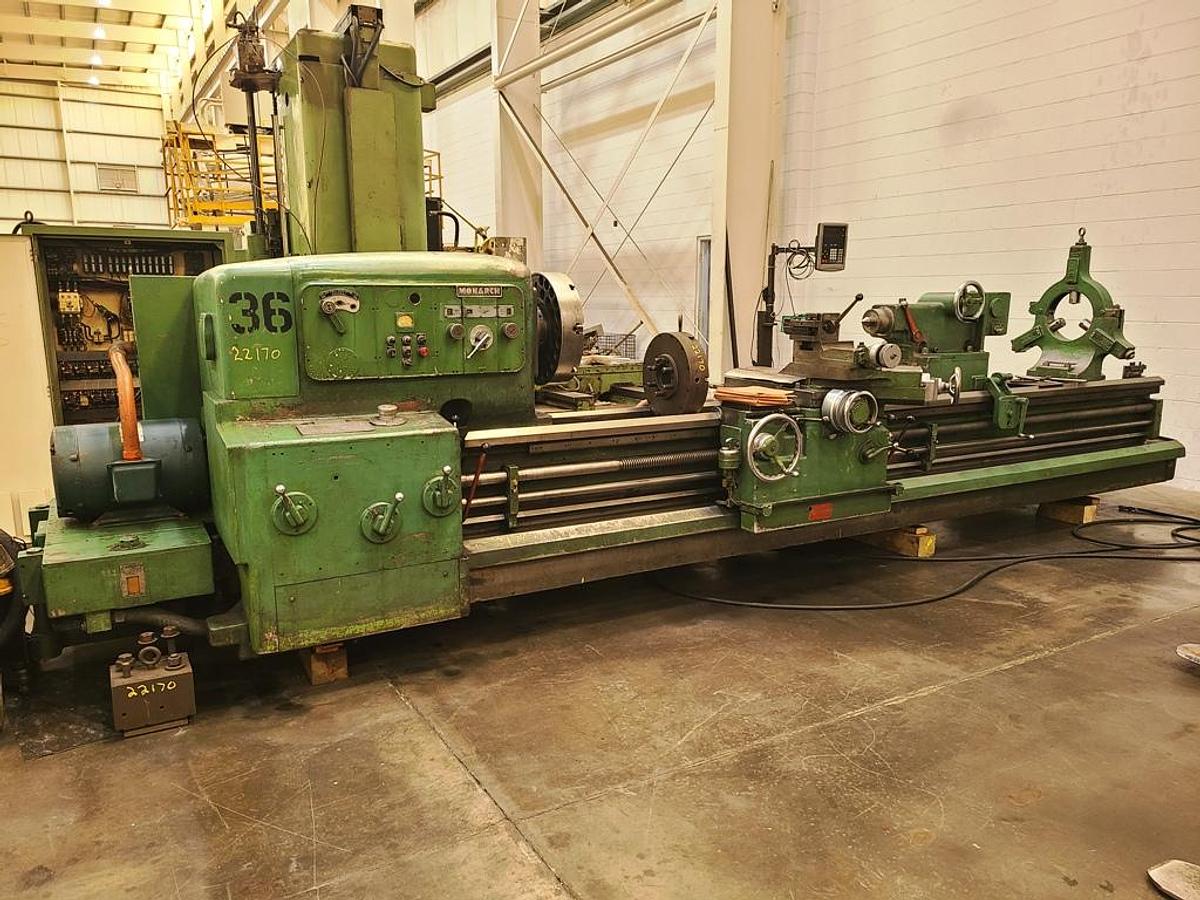

35" x 12' MONARCH ENGINE LATHE

35" x 12' MONARCH ENGINE LATHE

$29,500 (USD)

Available quantity:1

Description

PRICE: Loaded on Truck, Our Warehouse, York, PA ………… $29,500.00

HMC Stock # 22170

Machine Serial No.: 44561-AT

Machine Model No.: 2516-20 x 144 Series 80 Dyna Shift

New Date: November 1960

Swing Over Bed Ways: 35"

Swing Over Cross Slide: 19-1/2"

Spindle Bore: 3-1/8"

Spindle Nose Type: D1-8 Camlock

Spindle Speeds: 10 to 1250 RPM

(48) Threads: 1/2 to 28 TPI

(48) Feeds: 0.0030" to 0.1683 TPR

Tailstock Quill Diameter: 5-3/4"

Tailstock Set Over: 1/2" Each Direction

Tailstock Quill Travel: 10"

EQUIPPED WITH:

Newall Model C80 Two-Axis Digital Readout System

Thread Chasing Dial

Hydraulic Speed Selecting and Shifting

Quick Change Tool Post with Assorted Tool Holders

Hydraulic Variable Speed Rapid Traverse to Carriage and Cross Slide

Inch Graduated Dials on Carriage, Cross Slide and Top Compound

Fixed Angle Top Compound for Tracer System – Non-Swiveling

Geared Hand Crank Tailstock Positioner

Bijur One Shot Lubrication System on Carriage and Tailstock

Chuck and Camlock Wrenches

(2) 14" Diameter Drive Plates with D8 Camlock Mount

(1) 13" Diameter Roller Type Steady Rest

(1) 18" Cushman 3 Jaw Chuck with 2 Piece Jaws and Hard Reversible Top Jaws, D8 Mount

(1) 21 Cushman 4 Jaw Chuck with 1 Piece Hard Reversible Jaws, D8 Mount

(1) #6 MT Dead Center in Headstock, is Removeable

(1) Non Removeable Live Center Built Into Tailstock Quill

(1) Large Boring Bar Tool Holder, 9" x 10" x 6-1/2" High with 3" Thru Hole

Full Length Chip Pan

Hardened and Ground Bed Ways in Good Condition

Built in Coolant Pump

Micrometer Carriage Stop

Air Gage Tracer System with Full Length Template Bar – PARTS MISSING

30 HP Main Motor, Wired for 3 Phase, 60 Hz, 208/230/460 Volts

Presently Wired for 440 Volt Operation

Overall Size: 273" (22.75') x 83" FB x 79" High x 24,000 Lbs.

NOVEMBER 2025:

The original tracer system and components that were equipped on this machine have been removed and thrown away. The lathe still has a special fixed compound. The internal hydraulic components of the compound were removed. The compound was modified to accept an acme screw and nut. The compound now has manual movement but still on the fixed angle. You can move the compound back and forth on that axis, it uses a Bridgeport dial for measurement. It is manual movement; there is no power feed. The lathe was modified this way as it seemed to make sense from an aesthetic point of view. The other viable option was to remove the compound and saw or mill off the protruding arm. This axis of movement does NOT have a clamp.

Specifications

| Manufacturer | Monarch |

| Model | 2516-20 x 144 Series 80 Dyna Shift |

| Year | 1960 |

| Condition | Used |

| Serial Number | 44561-AT |

| Stock Number | 22170 |